In electronics manufacturing, uncertainty is the enemy of success. Unexpected delays, quality issues, and supply chain disruptions can derail even the best-designed products. At Digitron, we take a proactive approach to eliminate risks, ensuring a seamless, reliable production process—so you never have to deal with surprises.

Precision Starts with Planning

The foundation of predictable, high-quality production begins before manufacturing even starts. Our process begins with detailed planning, ensuring every component is sourced, every production step is optimized, and potential challenges are addressed upfront. By aligning with our clients from day one, we create a smooth, disruption-free workflow.

Advanced Automation for Consistent Results

Manual processes leave room for errors. That’s why we invest in state-of-the-art automation, ensuring that every product is built with uncompromising precision and repeatability. Our 7 SMT lines, real-time monitoring, and automated defect detection eliminate inconsistencies, so every unit meets the highest standards.

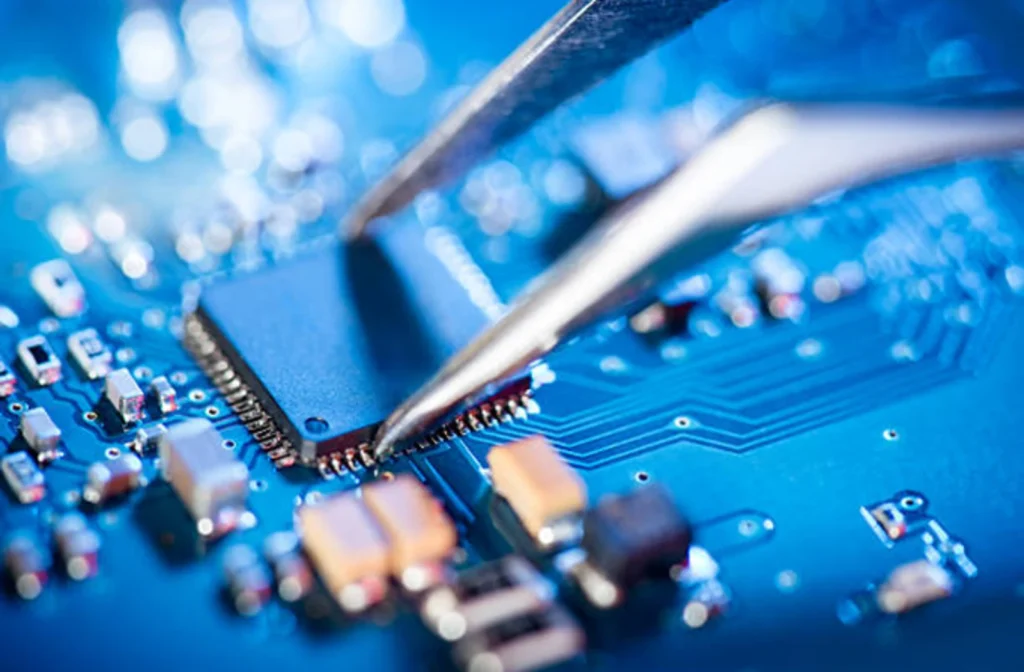

Extra Eye: Seeing Issues Before They Happen

At Digitron, we don’t just test products—we anticipate and prevent failures. Our Extra Eye inspection technology goes beyond traditional quality checks, ensuring first-article inspection with microscopic accuracy. This means flaws are caught before full-scale production begins, saving time, cost, and resources.

Supply Chain Resilience

Production delays often stem from component shortages or supply chain bottlenecks. With our strong global supplier network and strategic procurement strategies, we secure high-quality materials on time, keeping your production on schedule and avoiding last-minute surprises.

Seamless Execution, Every Time

When you work with Digitron, you get more than just a manufacturer—you get a partner who ensures your project runs smoothly, efficiently, and without unexpected obstacles.

Because in electronics production, the best surprise is no surprises at all.